To Determine If The System Is Leaking More Than The Allowable Rate

To determine if the system is leaking more than the allowable rate. See Module D for more information on leak rates EXEMPTION S OR EXCLUSIONS Leak repair provisions of this regulation do NOT affect systems normally containing 50 pounds or less of refrigerant. Must have the leaks repaired within 30 days of determining that the leak rate exceeds the allowable rate Must notify EPA if more than 30 days are needed to complete a repair eg. Replacement component will not be available within 30 days.

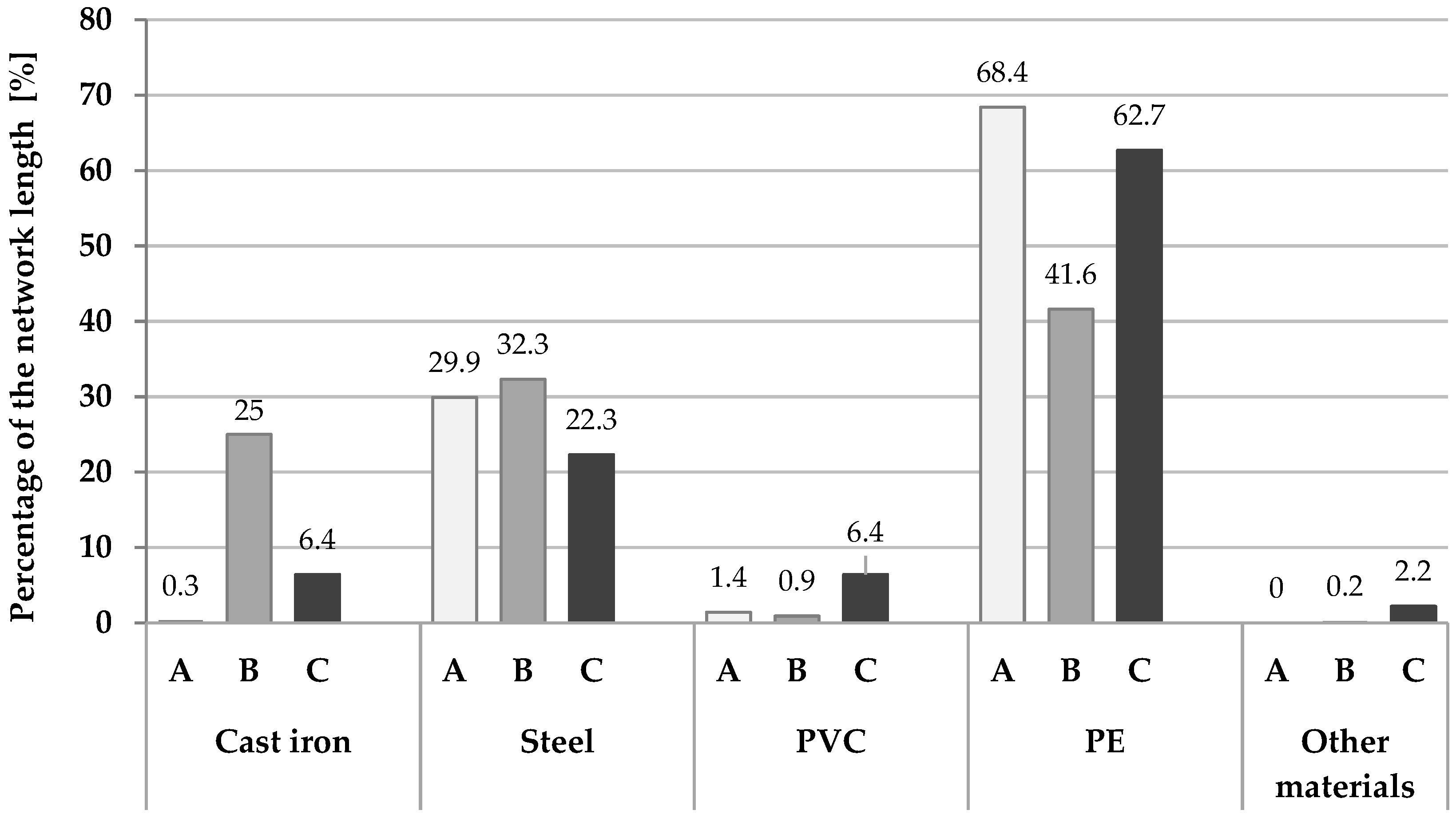

You can also refer to graphs for each testerplate combination. The Influence of the Temperature on the Leak Flow-rate 8. Annualizing and rolling average.

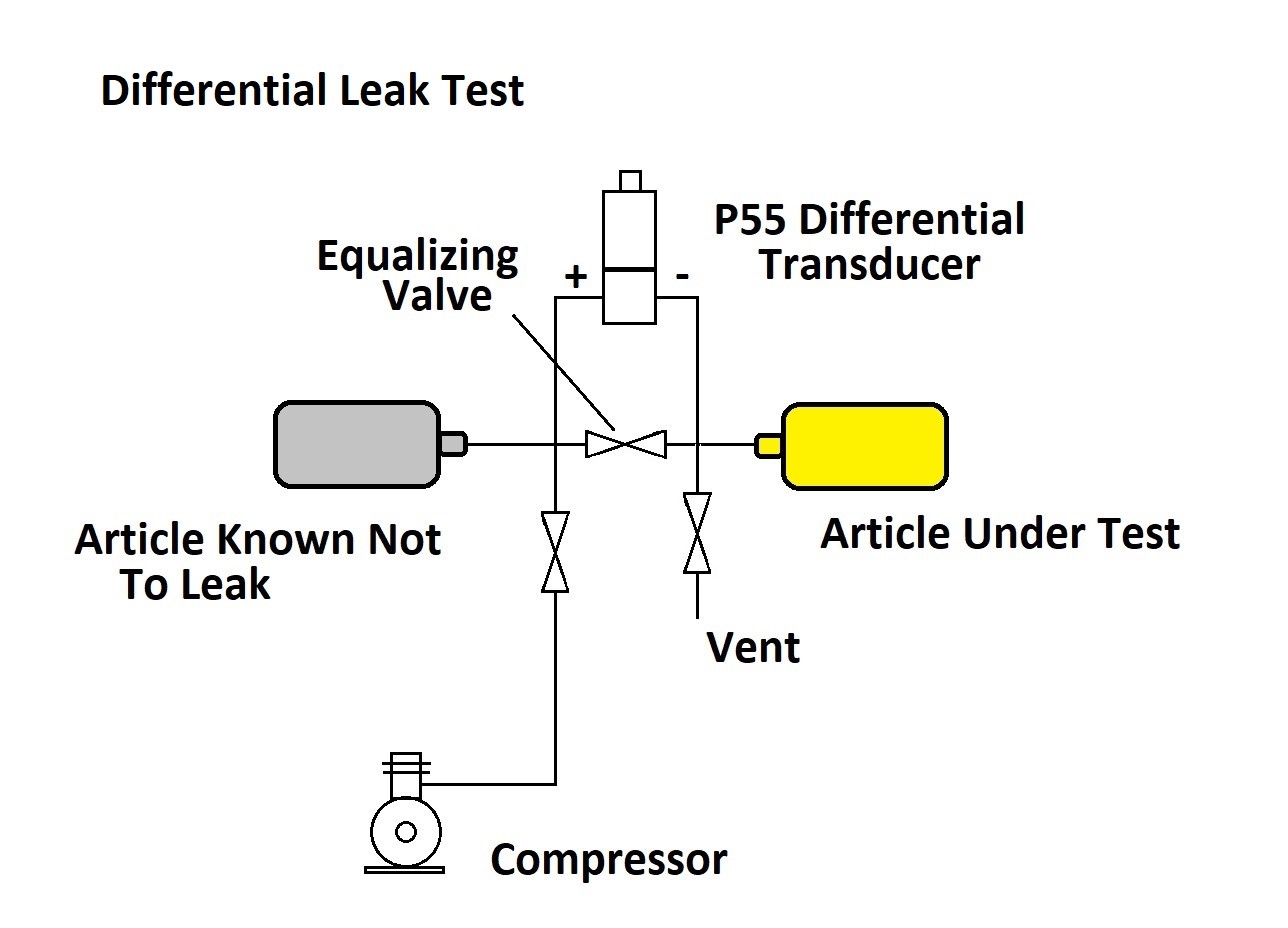

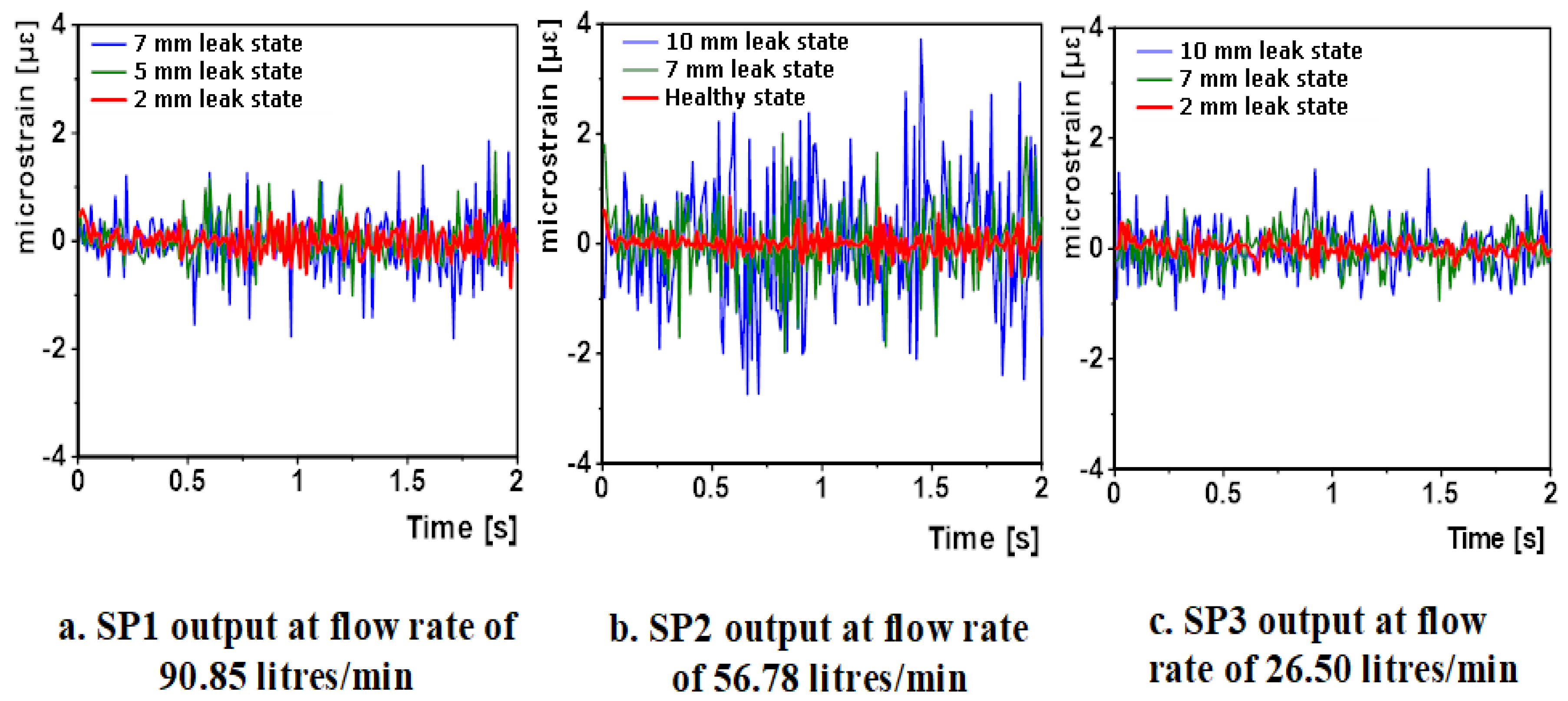

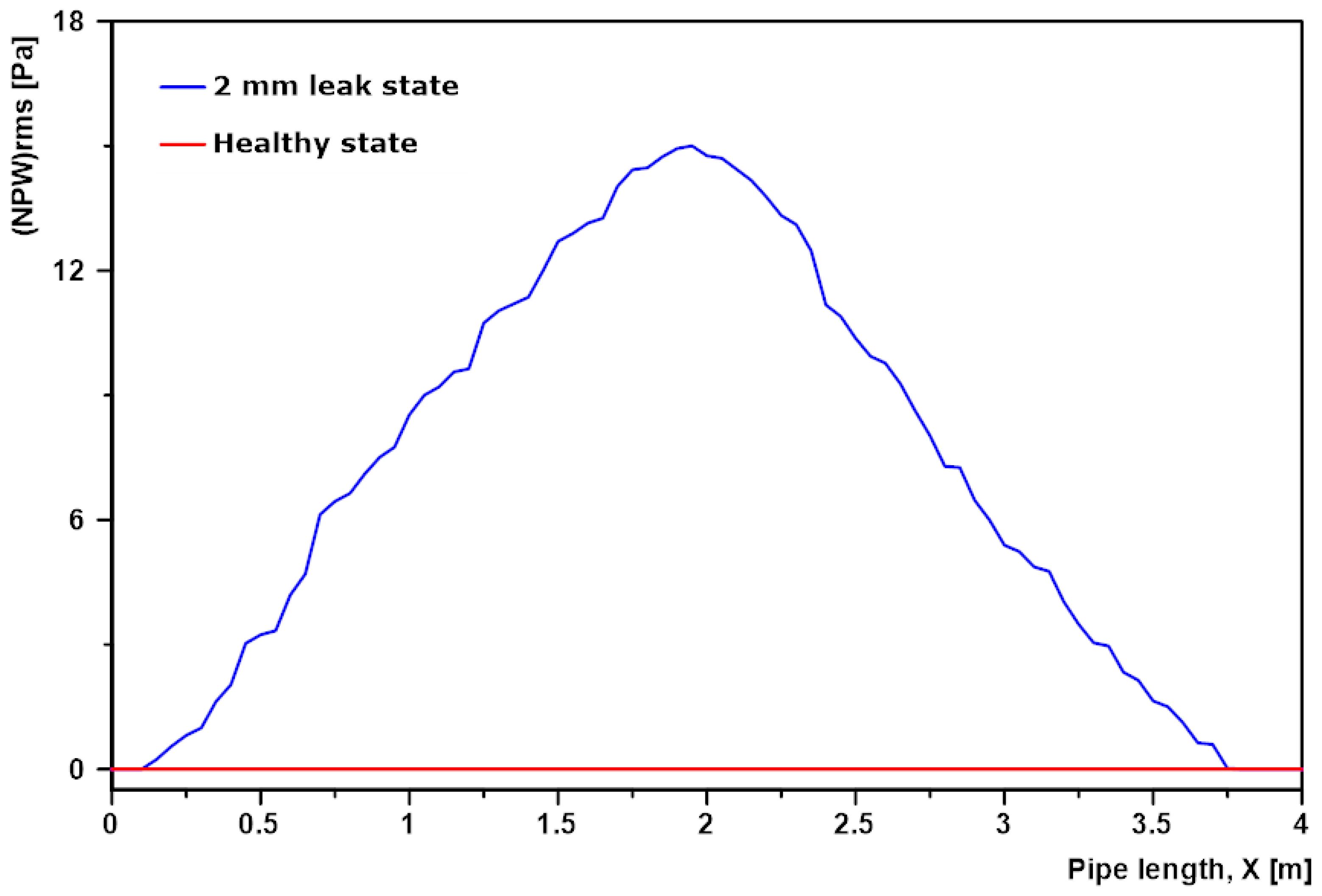

This method is good for research studies and for attempts to correlate energy use to leakage. The characteristics of the hole or leak that determine whether it will leak are the smallest diameter in the hole path the path length of the hole through the part material surface tension and the surface finish of. Active test test performed on a completed functioning system This method would measure the actual leakage at a given point in time for the system under the operating conditions at that time.

In order to avoid service call fees we recommend the customer take the following steps to determine the source of their leak. In both cases the requirements are the same. ----- EPA 30O-B-95-010 discovery of the exceedance of the leak rate the owner of the system voluntarily mothballs the system for a period of time the requirement to repair leaks or retrofit or retire me system is suspended for that same time period For example if the system operated for five days after discovery of the exceedance of the leak rate and then was shut down and mothballed for two months when the.

Tracker system determine the liquid level of the tank by measuring differential pressure between the top and bottom of the tank. When leaks happen its important to identify them quickly then determine the cause. According to the latest rule there are two acceptable methods for calculating leak rate.

3 to RetroÐLRetirernent Opüon or retire the leaking equipment Proceed through the remainer of the flow chart to determine if time beyond one yeE is permiaed. For commercial refrigeration equipment EPA says the trigger leak rate for a 12-month period is 35 percent of the full charge. The temperatures of product inside a shell and tube heat exchanger can vary dramatically.

Process refrigeration system discovers that refrigerant is leaking at a rate that would exceed 35 percent of the total charge in a 12-month period. Here is an example.

The detectable leak rates are significantly lower than the leak rates which must be detected in practice.

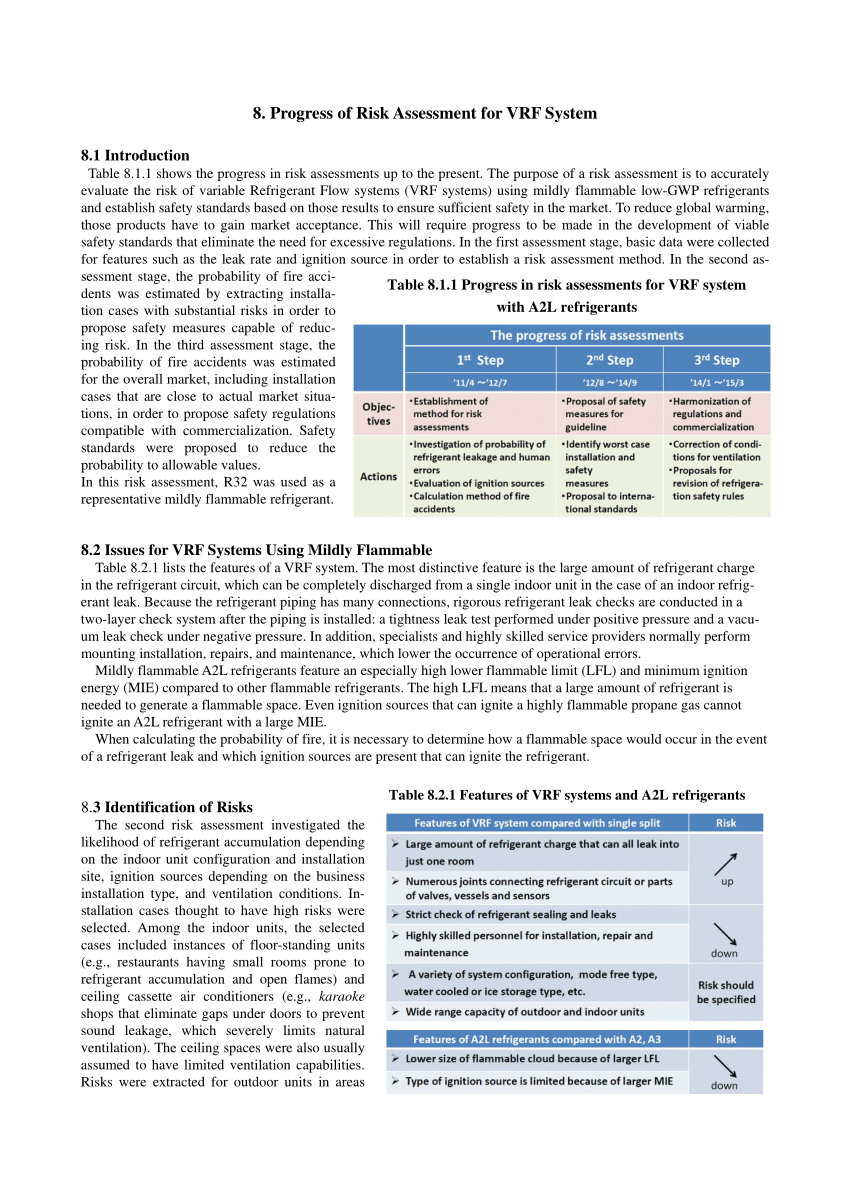

For commercial refrigeration equipment EPA says the trigger leak rate for a 12-month period is 35 percent of the full charge. Approximately 53 times more units of volume through a hole than water if the water is able to flow at all. Locate your water meter A. Process refrigeration system discovers that refrigerant is leaking at a rate that would exceed 35 percent of the total charge in a 12-month period. The water meter will be located inside an oval cast iron box approximately 12 long. For commercial refrigeration equipment EPA says the trigger leak rate for a 12-month period is 35 percent of the full charge. First Step Preliminary layout of the system Second Step Determine the amount of refrigerant Third Step Verify that the VRV system layout complies with Standard 15 requirements Fourth Step. In both cases the requirements are the same. When leaks happen its important to identify them quickly then determine the cause.

See Module D for more information on leak rates EXEMPTION S OR EXCLUSIONS Leak repair provisions of this regulation do NOT affect systems normally containing 50 pounds or less of refrigerant. Conversion for Different Pressure Conditions 7. Must have the leaks repaired within 30 days of determining that the leak rate exceeds the allowable rate Must notify EPA if more than 30 days are needed to complete a repair eg. More than 20 idle time is excessive. Check to make sure the ECM is. Approximately 53 times more units of volume through a hole than water if the water is able to flow at all. The Influence of the Temperature on the Leak Flow-rate 8.

Post a Comment for "To Determine If The System Is Leaking More Than The Allowable Rate"